When using multi-hole vacuum chucks, why is it necessary to install an automatic air-liquid separator? This question relates to the working principles of vacuum pumps and the characteristics of vacuum chucks. Let me explain.

Multi-hole vacuum chucks are commonly used fixtures in CNC machining for clamping non-magnetic flat sheets. They find frequent application in three-axis CNC machining centers and flat surface grinders. The working principle involves using vacuum force (created by low pressure inside the vacuum) to securely hold workpieces onto the vacuum chuck. When the vacuum chuck closely contacts the work surface, a connection pipe links the vacuum chuck’s internal cavity to the vacuum pump. The vacuum pump evacuates the air from within the vacuum chuck, generating suction.

During operation, if the workpiece area is sprayed with coolant, a small amount of coolant and fine debris particles may be drawn into the gap between the workpiece and the vacuum chuck’s adherent surface. The vacuum pump then extracts this gas-liquid mixture from the vacuum chuck. Without an air-liquid separator installed between the vacuum pump and the vacuum chuck, this mixture could enter the pump’s air reservoir.

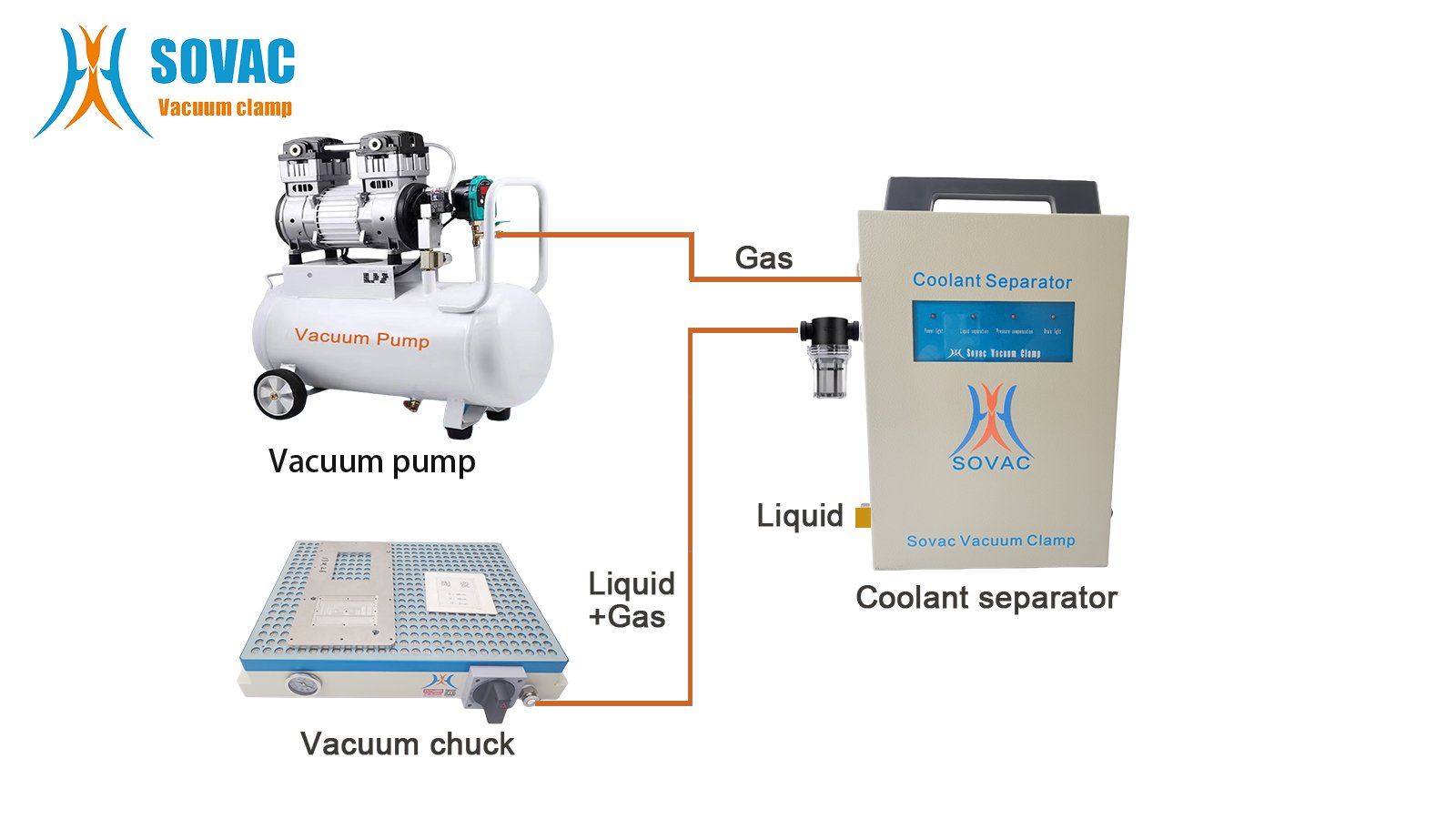

Coolant not only damages the vacuum pump but also affects its pumping speed, subsequently impacting the vacuum chuck’s suction force. Therefore, it is essential to separate the coolant that enters the vacuum cup. The purpose of an gas-liquid separator is precisely that—to separate liquid and gas within the vacuum chuck. When the vacuum chuck operates, it may inadvertently draw in some liquid (such as cutting fluid or water vapor). If this liquid reaches the vacuum pump, it could clog or damage the pump, potentially shortening its lifespan. The automatic air-liquid separator prevents such liquids from entering the vacuum pump, ensuring its normal operation.

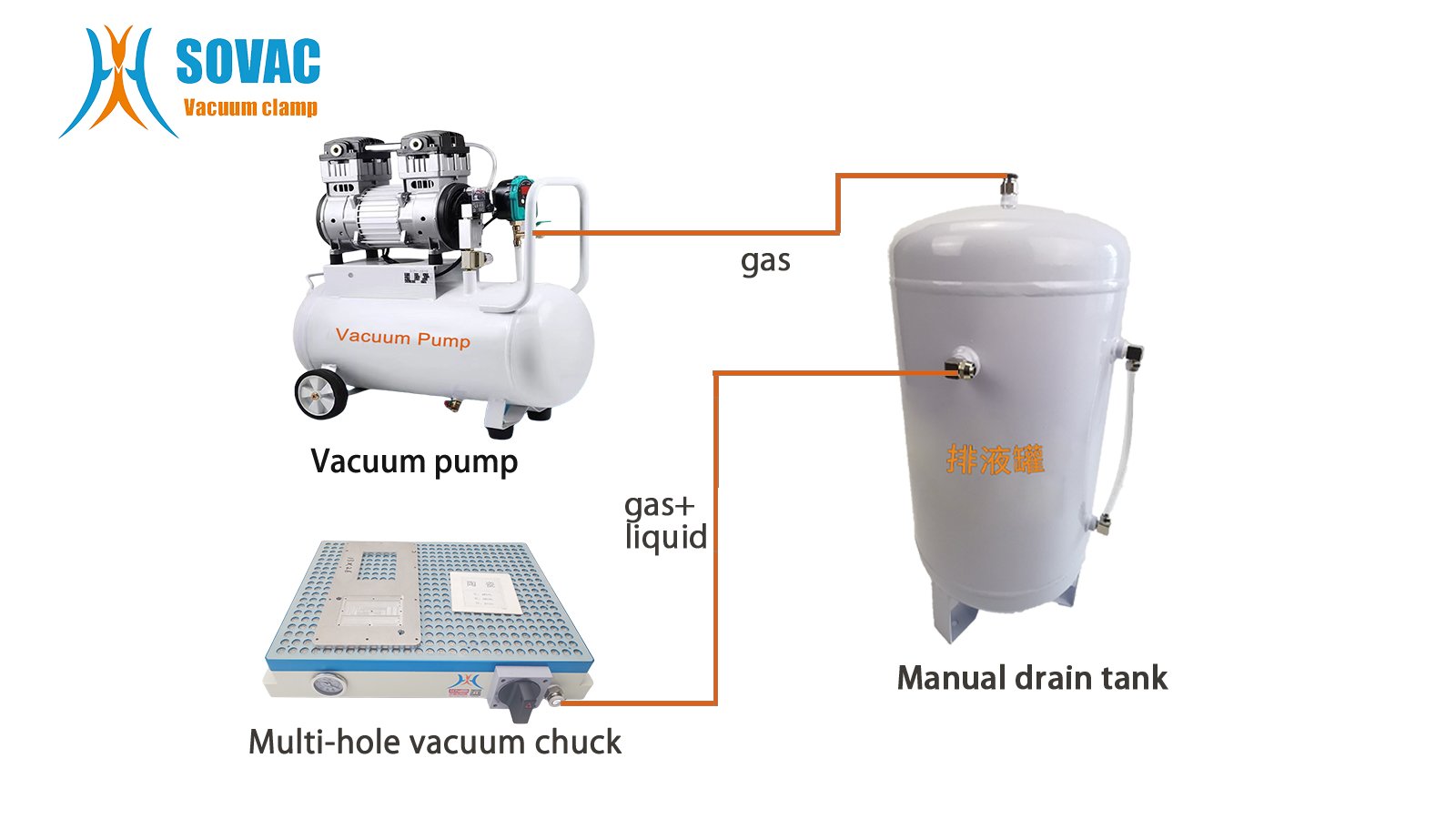

In the past, a liquid drainage tank was sometimes installed between the vacuum chuck and the vacuum pump. This tank relied on the principle that liquids are denser than gases. As the gas-liquid mixture entered the drainage tank, the liquid settled at the tank’s bottom, while the gas was drawn away by the vacuum pump. However, drainage tanks had a drawback. During prolonged drilling and milling operations (which can last several hours), coolant could accumulate in the tank. Operators had to pause work, drain the coolant manually, and then resume machining, affecting efficiency—especially for precision workpieces where interruptions were undesirable.

Enter the automatic gas-liquid separator. It addresses the aforementioned issues and offers several clear advantages:

1. Compact size, minimizing workshop space requirements.

2. No manual adjustments needed; it adapts as liquid volume increases, shortening drainage cycles.

3. Continuous liquid drainage without manual intervention.

4. Low power consumption.

5. High protection level, suitable for internal placement within machining centers.

6. Ability to filter out fine debris during drilling and milling processes.

In summary, configuring an automatic gas-liquid separator ensures proper functioning of multi-hole vacuum chucks while safeguarding vacuum pumps from liquid interference. By automating liquid separation, it reduces the hassle of manual drainage. Truly, the air-liquid separator is an excellent companion and helper for both vacuum cups and vacuum pumps.