Useful Links

Sichuan Ditrong Technology Co.,Ltd.

Quick Links

- Ditrong Dai

- +86 18280225017

- ditrong@outlook.com

- (+86) 18280225017

- 1st Floor, No.282-288 zhonghe Gongjiqiao Road, High-tech Zone, Chengdu, China

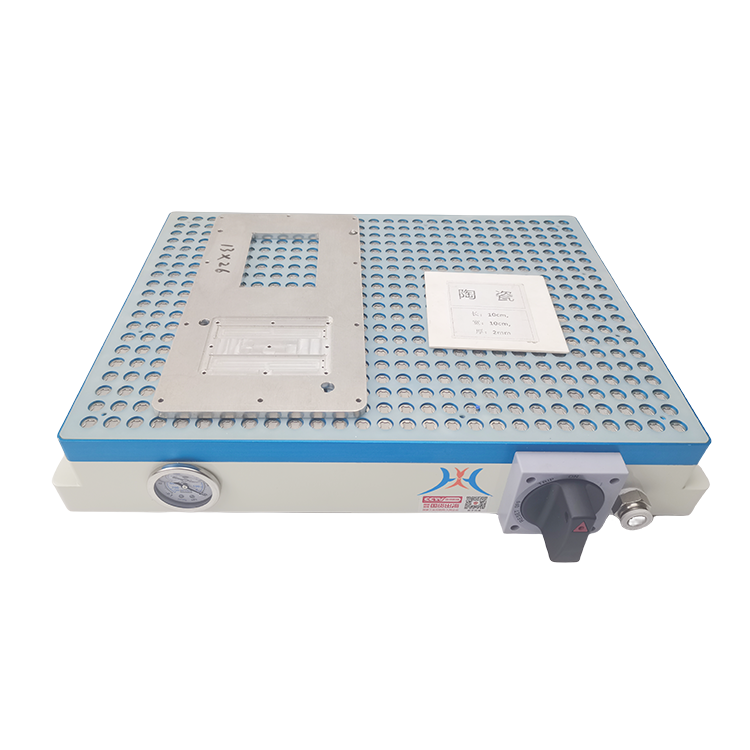

CNC Automatic valve type multi-hole vacuum table, No need to install sealing rubber cord, Complete clamping in 1 second. Allow workpiece milled through. Each suction hole works independently. There is an independent automatic valve in every suction hole. When the surface of the suction hole is not covered by the workpiece, the internal valve of the suction hole automatically closes. When the surface of the suction hole is covered by the workpiece, the internal valve of the suction hole opens. Form an air pressure difference on the upper and lower sides of the workpiece, and the workpiece is firmly sucked on the surface of the vacuum table. Irregular shaped workpiece can be sucked. When workpiece is milled through, Suction hole in other places that are not milled through works normally. Suction force continues to maintain.

Each suction hole works independently.

There is an independent valve inside of each suction hole. Allows drilling and milling through the workpiece.

Holding irregular shaped workpieces.

No need to install sealing cord or cover the area outside the workpiece with rubber mat.

Has only one connector which is connected to vacuum system, self-cleaning functions, no need reverse jet.

Replaceable aluminum alloy plate.

Replaceable plate can be milled multiple times. Ensure higher machining accuracy. Users can download the drawings of replaceable plates and machine a new one.

The basic functions are the same as the primary version.

More suction holes than primary version under the same area.

Higher body thickness for improved worktable accuracy.

Built-in gas storage compartment.

Stronger suction force.

Only one switch, operate easily.

Two modes of automatic and manual self-cleaning.

You can download the replaceable plate drawing files on the support page and process a new one.

The features are the same as the professional vacuum table, but the suction holes have smaller diameters and smaller center hole distances, resulting in more suction holes than professional version on the same working face.

The features are the same as the Primary vacuum table.

With smaller and denser suction holes.

Used on rectangular surface grinder.

Nonferrous and nonmagnetic materials can be held.

Both dry and fluid surface grinder are applicable.

Circular vacuum chuck can be customized and applied to the rotary surface grinder.

LCD display information panel.

Higher suction flow rate

Pure copper motor.

The high and low thresholds have been set at the factory.

Intelligent completely automatic drainage.

The separated cutting fluid can be pumped to a higher position tank(Pump head 6m).

Sichuan Ditrong Technology Co.,Ltd.

Get an instant quote from our most experienced consultants.