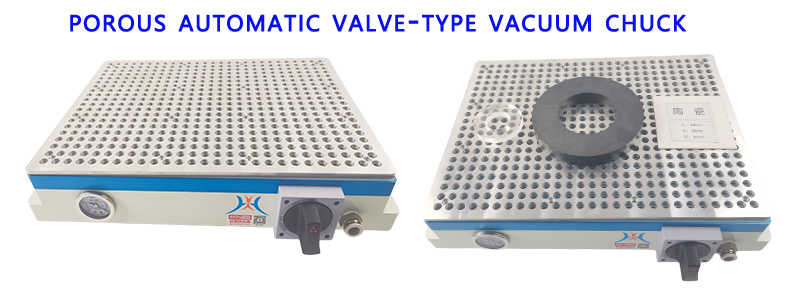

The basic principle of the porous automatic valve-type vacuum chuck is similar to that of the sealing strip vacuum chuck. Both utilize the pressure differential formed on the upper and lower sides of the workpiece to generate suction force, securely adhering the flat workpiece to the vacuum chuck’s worktable. However, the porous automatic valve-type vacuum chuck differs in that it features numerous independent suction holes on the chuck worktable, with each suction hole operating independently, irrespective of the working status of other suction holes.

We can conceptualize that while using a sealing strip vacuum chuck, we create a unified suction force within the enclosed area. Applying the same concept to the porous automatic valve-type vacuum chuck, it comprises numerous fixed circular holes, forming smaller suction units that collectively generate an overall suction force. Correspondingly, as the workpiece area increases, covering more independent suction holes, the suction force strengthens. This division of the overall suction force into many small suction units (with each independent suction hole being a suction unit) results in a weaker suction force for a workpiece placed on a porous automatic valve-type vacuum chuck compared to a sealing strip vacuum chuck of the same area. This understanding aligns with the formula F = P * S, where a decrease in area leads to a reduction in suction force.

Additionally, we can infer that among two porous automatic valve-type vacuum chucks of the same size, the one with denser suction hole designs will exert greater suction force.

The working principle of the porous automatic valve-type vacuum chuck should now be clear. Let’s now discuss its key characteristics. Firstly, it overcomes the limitation of not being able to mill through the workpiece when using sealing strip vacuum chucks. With porous automatic valve-type vacuum chucks, if a certain area of the workpiece is milled through, only the exposed suction holes in that area will automatically close. As long as the remaining working suction holes are sufficient, the workpiece will continue to be firmly held. This makes it the best choice for situations requiring one-time milling through of workpieces. Secondly, when processing small-area semiconductor workpieces, it offers quicker and more convenient fixation than trying to fit a suitable sealing ring around them. For example, a 10cm * 10cm ceramic workpiece can be easily placed on a porous automatic valve-type vacuum chuck for rapid adsorption.

Furthermore, if a thin plate workpiece becomes a partially finished product with perforations after processing, preventing the use of sealing strip vacuum chucks, porous automatic valve-type vacuum chucks can still be employed. Lastly, in scenarios where ultra-thin workpieces are involved, using sealing strip vacuum chucks may result in excessive suction force, causing deformation. However, placing such ultra-thin workpieces on porous automatic valve-type vacuum chucks eliminates this issue due to the chuck’s flat surface. Additionally, in such cases, the suction force of individual holes in the porous automatic valve-type vacuum chuck can be adjusted to prevent deformation at each suction hole, which is highly practical in semiconductor material thin plate processing.

In summary, the four main advantages can be summarized as follows: 1. Suitable for one-time milling through of workpieces; 2. Offers faster and more convenient fixation for small-area workpieces; 3. Can adhere to partially finished workpieces with perforations; 4. Provides better overall support for ultra-thin workpieces, preventing deformation.

However, there are also some inconveniences associated with its usage. Firstly, it requires higher flatness and parallelism of the workpiece. Before processing on a porous automatic valve-type vacuum chuck, it’s essential to ensure that the workpiece’s flatness and parallelism meet the requirements, generally requiring flatness within 3.2μm and parallelism within 0.2mm, with minimal bending of the workpiece. Secondly, during the drilling and milling process using porous automatic valve-type vacuum chucks, if cutting fluid is needed, it may enter the suction holes covering the workpiece area through the gaps between the workpiece and the chuck surface. This issue is not encountered when using sealing strip vacuum chucks. Sometimes, the amount of fluid can be significant. However, this problem is effectively addressed in SOVAC VACUUM CLAMP’s vacuum chucks, as they are equipped with an automatic drainage device. This small device eliminates the need for manual drainage at regular intervals.