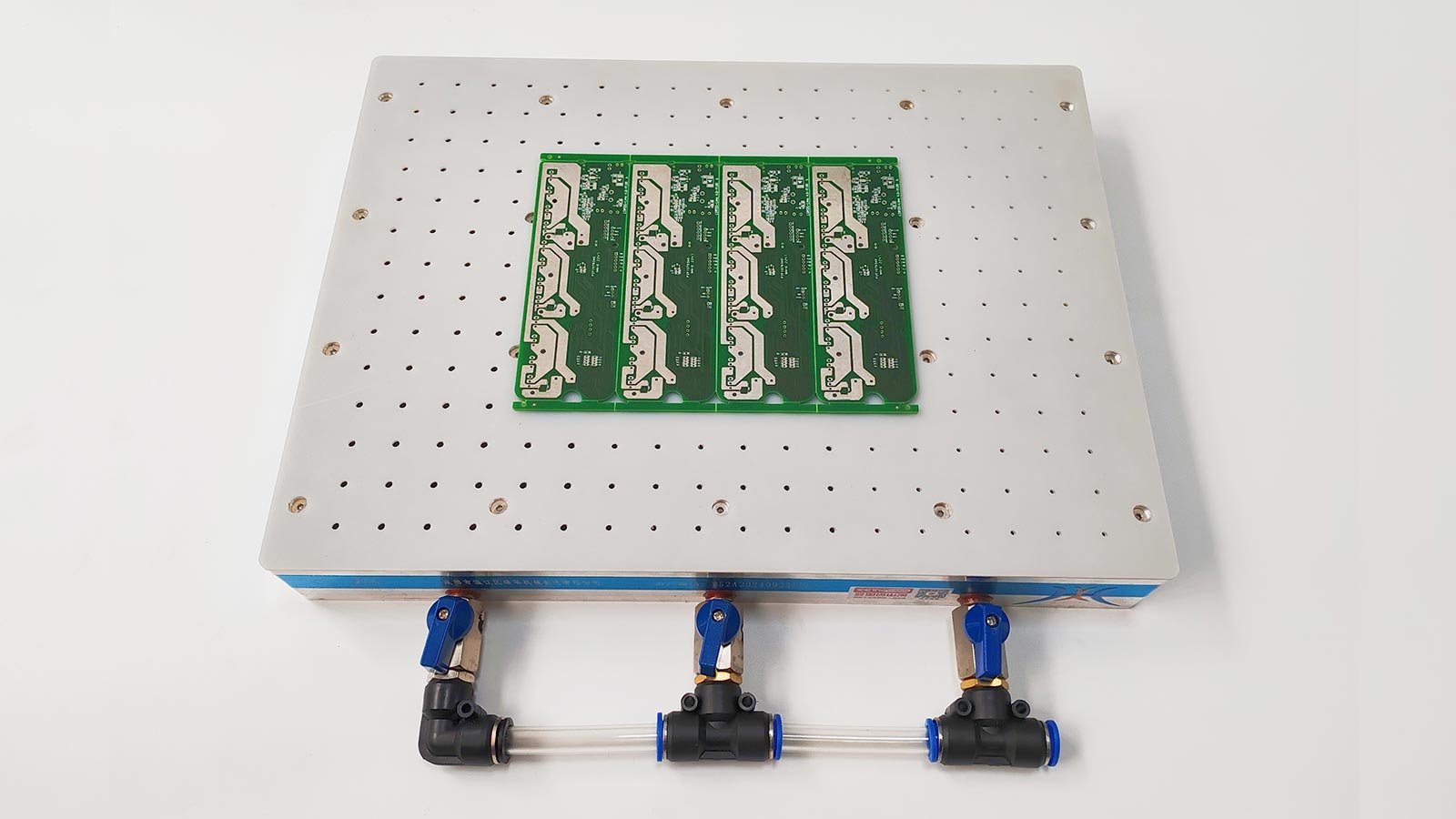

Vacuum Fixture for Printed Circuit Board with Holes

These fixture utilize vacuum technology to hold the PCB firmly and evenly, ensuring accurate and efficient processing. They are particularly suitable for ultra-thin printed circuit boards with holes. Vacuum Fixture for Printed Circuit Board with Holes can quickly fix PCB with holes to facilitate subsequent depanelling or patching operations. It is particularly suitable for fixing printed circuit boards when using CNC router or CNC milling. The suction force can be pre-adjusted, and the spacing and diameter of the suction holes can be customized. A positioning auxiliary device can be installed on the adsorption work surface to achieve accurate positioning of batches of PCBs of the same size.

Printed circuit boards are generally made of polymer resin materials, and the thickness is generally between 0.3 and 4mm. Traditional magnetic chucks or vises cannot fix them. Vacuum Fixture for Printed Circuit Board with Holes uses hundreds of independently working suction holes. Whether a certain suction hole provides suction is determined by the pressure difference between the vacuum inside and the atmosphere. The area without holes on the printed circuit board covers the suction holes and will be adsorbed. If the hole on the printed circuit board coincides with the suction hole, the suction hole will be closed and no suction will be generated.Therefore, printed circuit boards with holes can be firmly fixed. This is generally suitable for hard printed circuit boards. If it is a FPCB (flexible printed circuit board) with a thickness of about 0.1mm, it needs to be redesigned and customized.

Vacuum Fixture for Printed Circuit Board with Holes features

- Suitable for 0.3mm~4mm thickness circuit boards with or without holes.

- The suction force can be customized.

- The diameter of suction holes can be customized(0.3~2mm).

- The adsorption working surface is made of silicone.

- Can withstand UV lamp.

- High temperature resistance of 120°C.

- Allow users to design positioning auxiliary devices.

- A single independent circuit board is not less than 8cm*8cm.

- The height of the copper layer above the substrate does not exceed 0.175mm.

- Flatness of vacuum fixture: 0.05mm (Every 500mm)

When to use vacuum fixture for PCB with holes

- It is required that the printed circuit board cannot warp.

- The printed circuit board needs to be fixed flatly.

- The printed circuit board is too thin or too soft to be clamped using a hard clamp.

- Printed circuit boards come in many sizes。

- Printing on printed circuit boards.

- Plug holes in printed circuit boards.

- Tinning of printed circuit boards.