1. Background of the Scheme

In order to process metal components more efficiently and accurately, the application of automated production lines on CNC machining centers is becoming a trend. There are many differences between automated production lines and traditional manual operation of CNC machining centers. Programmatic, accuracy, unmanned operation, and uninterrupted operation are the four main characteristics of automated production lines. For drilling and milling of some hollow non-magnetic thin sheet workpieces, if automation is needed in the operation, we need to use gasket chucks as vacuum clamping tools in the clamping process.

2. Analysis and Comparison of Vacuum Chucks

Vacuum chucks are mainly divided into gasket vacuum chucks and non-gasket vacuum chucks, which can also be called porous vacuum chucks. This type of porous vacuum chuck is further divided into spring valve core porous vacuum chucks and non-spring valve core porous vacuum chucks.

Let’s first analyze whether gasket vacuum chucks can be used on the production line of automated CNC machining centers. Gasket vacuum chucks require manual pre-sealing of a sealing shape smaller than the workpiece shape according to the workpiece’s shape, and the material of the gasket is generally EPDM rubber. Obviously, this requires manual intervention, which is not feasible for unmanned automated production lines, not to mention that some workpieces require milling and drilling through the workpiece. Therefore, gasket vacuum chucks cannot be applied on the production line of automated CNC machining centers.

As for the remaining spring valve core porous vacuum chucks and non-spring valve core porous vacuum chucks, which one is more suitable for use on the production line of automated CNC machining centers? Let’s first analyze the spring valve core porous vacuum chuck. This type of vacuum chuck has a large market share domestically. Its advantage is that it can hold thin sheet workpieces and allows milling and drilling through the workpiece. However, if used on automated production lines, there will be several main difficulties that are relatively difficult to overcome. First of all, this type of vacuum chuck needs positive pressure intervention to perform backwashing of the chuck after each drilling and milling operation to flush out the tiny chips and residual cutting fluid that have entered the chuck. This poses certain requirements on the programming of the CNC machine, requiring an additional backwashing program. Although the issue of backwashing is somewhat challenging, it should be possible to overcome it with some effort. However, the filter mesh of this type of chuck will become blocked after some time of use, causing a decrease in air permeability, and the valve core needs to be replaced manually. This will cause significant time loss for automated production lines. Moreover, when processing ceramics, glass, quartz, fiberglass, graphite, and other workpieces, the clogging cycle of the filter mesh will be shorter, with individual air intake holes becoming blocked after just three days of use. Finally, only the non-spring valve core vacuum chuck is left, which is most likely to be compatible with the production line of automated CNC machining centers.

Non-spring valve core vacuum chucks have the following characteristics:

1. The internal structure of the valve core adopts a non-spring structure, effectively avoiding clogging of the filter mesh. The internal gas passage no longer uses a ring clearance of about 0.05mm like the spring valve core, but instead uses a 2mm diameter circular hole gas passage with a 0.17mm filter mesh design. Whether the debris generated by drilling and milling is in chip form or powder form, it can pass through the gap between the workpiece and the chuck surface (which is firmly pressed due to suction) and is generally less than 0.1mm. Therefore, all the debris sucked into the chuck at the location covered by the workpiece can pass through the filter mesh and the valve core gas passage. Since the valve core is closed and there is no suction force in the area outside the workpiece covering, debris will not enter the interior of the chuck through the suction holes outside the workpiece covering. This ensures that the debris inside the chuck is all less than 0.1mm, easily passing through the filter mesh (0.17mm mesh) and the valve core gas passage (Φ2mm). This chuck overcomes the problem of filter mesh clogging from a structural design perspective and the valve core does not need to be replaced for several years of continuous use.

2. Non-spring valve core vacuum chucks have pneumatic self-cleaning function and do not require backwashing. Compared to porous vacuum chucks that require backwashing, there is one less backwashing procedure, and the spring valve core that requires backwashing often needs to be connected to a positive pressure air pipe. The non-spring valve core vacuum chuck only needs a single negative pressure air pipe, and the structure is simpler. The control requirements for the solenoid valve are relatively much simpler.

Non-spring valve core vacuum chucks have pneumatic self-cleaning function, replacing the backwashing operation of the spring valve core. After processing the workpiece, at the moment when the chuck switch is closed, the air circuit is not completely blocked, but a relatively small amount of air is used to self-clean the chuck. Air enters the interior of the chuck through all the suction holes, continuously extracting residual cutting fluid and tiny chips until a new workpiece is placed on the chuck worktable, and the switch is reopened to hold the workpiece, thereby automatically ending the self-cleaning action.

3. Non-spring valve core vacuum chucks are equipped with a combination of soft and hard plates. The chuck body adopts an embedded nano-silicone soft plate design, which has good elasticity. It has been proven that milling through the workpiece with a depth of less than 0.05mm will not damage the soft plate. The vertical processing accuracy is between 0.03-0.05mm. Under normal circumstances, the soft plate needs to be replaced only once every 3 years. A replaceable hard plate can also be installed on the soft plate, which is designed specifically for high-precision machining and frequent milling through of workpieces. However, the hard plate needs to be surface-ground (sometimes called “polished”) after a period of use to remove the indentations left by repeated milling through.

3. Project Proposal Introduction

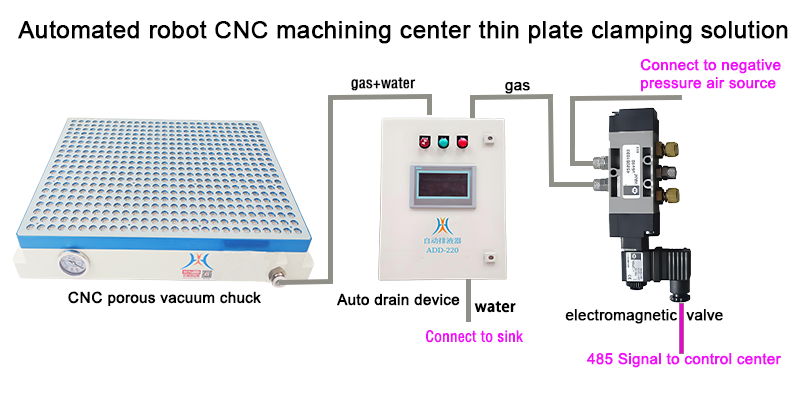

1. Equipment Connection Scheme

The above figure shows the standard unmanned CNC machining center vacuum chuck equipment connection diagram. The vacuum chuck has a single negative pressure interface, which is connected to the automatic liquid discharger through a Φ12mm PU hose. The liquid discharger can achieve uninterrupted automatic liquid discharge for a long time without human intervention and can maintain pressure without reduction (automatic pressure maintenance), and it returns the cutting fluid to the machining center tank. The automatic liquid discharger comes with a magnetic suction patch, which can be directly attached to the inside or outside side walls of the machining center. The solenoid valve with PLC programming function realizes the switch control of the air circuit. The negative pressure air source can be configured according to the user’s situation with positive pressure + vacuum generator, or directly use a vacuum pump. It is recommended to use a vacuum pump in this scheme to reduce workshop noise pollution.

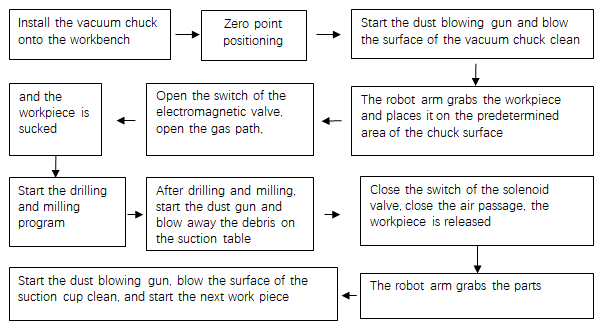

2. System Operation Flow