In the CNC machining industry, some precision CNC machining of non-magnetic thin plate workpieces does not require coolant. Furthermore, using a vacuum table allows for more convenient and quick clamping of the workpiece. Is the SOVAC vacuum table suitable for dry machining without coolant? Will the powder and debris generated by dry machining cause the suction holes of the SOVAC vacuum table to become clogged and ineffective?

First, let me explain how the SOVAC vacuum table works. Unlike traditional grid vacuum tables and sealed rope vacuum tables, the SOVAC table is composed of hundreds of suction holes arranged in a matrix pattern. Each suction hole houses a pressure differential sensing valve. When no workpiece is placed, the switch is turned on, and vacuum air rapidly enters the vacuum table’s cavity, creating a pressure differential at each suction hole, causing all valves to close instantly. This prevents vacuum loss. When a workpiece is placed in a limited area, the switch is turned on, and vacuum air rapidly enters the table’s cavity, creating a pressure differential only within the suction holes in the area not covered by the workpiece. At this time, the suction holes not covered by the workpiece will be completely blocked, while the suction holes covered by the workpiece will form an air pressure difference between the upper and lower sides of the workpiece due to the continuous presence of vacuum air. The vacuum clamping force of SOVAC comes from this air pressure difference.

If cutting fluid is sprayed during machining to cool the cutting tool, this cutting fluid will not be drawn into the vacuum table through the suction holes uncovered by the workpiece because these holes are completely blocked. Only a small amount of cutting fluid and fine cutting chips are drawn in through the gap between the workpiece and the clamping surface of the vacuum table. The amount of cutting fluid and fine cutting chips drawn in is very small. However, to prevent this cutting fluid and fine cutting chips from being drawn into the vacuum pump, a cutting fluid and chip collection device is typically installed between the vacuum table and the vacuum pump. If cutting fluid is not sprayed during machining, this type of machining without cutting fluid is generally referred to as dry machining. Using a SOVAC vacuum table, a small amount of powder will still be drawn into the vacuum table through the gap between the workpiece and the clamping surface. Common materials used for this type of dry machining include graphite, ceramics, and PCBs. The vacuum table operation methods differ between wet and dry machining processes.

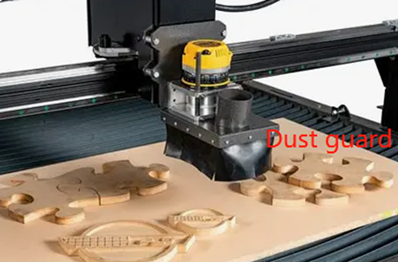

Let’s first explain the wet machining method. Since cutting fluid is continuously sprayed from the universal cooling tube during machining, the resulting chips are easily washed away by the water flow. The resulting chips roll off the vacuum table and workpiece, preventing them from accumulating on the table surface. However, during dry machining, if a dust guard is not used, dry powder produced by cutting can accumulate on the table surface.

Without a dust guard, the lifespan of the vacuum table will be greatly reduced. If a dust removal device is not available, we need to use a dust blower to blow away the accumulated dry powder after machining the workpiece. Ensure that the powder is blown away completely before turning off the vacuum table. This will reduce the amount of powder that falls into the vacuum table cavity.

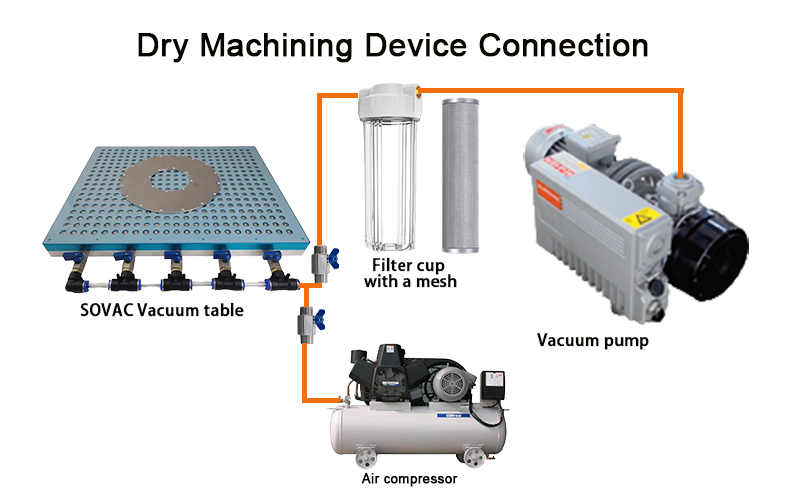

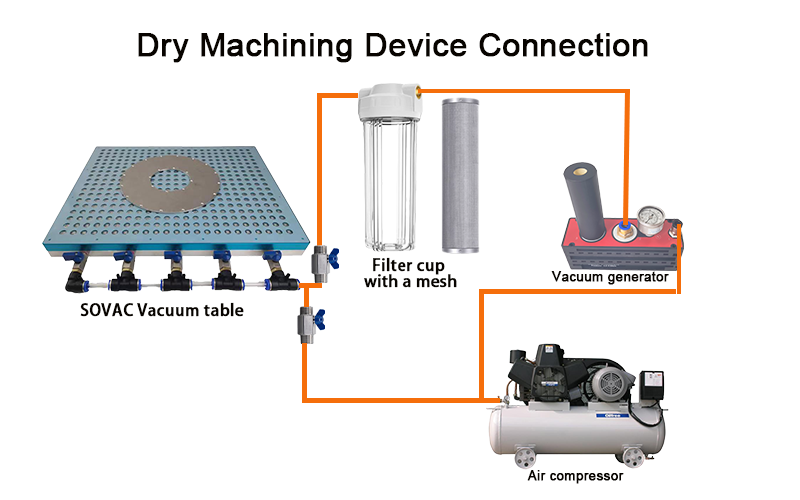

When dry machining a workpiece, a filter cup with a mesh is installed between the vacuum table and the vacuum pump. The mesh size of the filter screen should be determined based on the workpiece material being machined. The mesh size of the filter screen should be selected based on the particle size of the chip generated during machining. While using a vacuum generator can reduce damage to the vacuum acquisition equipment caused by powder and debris, it does compromise clamping force. Choosing the right vacuum acquisition equipment depends on the size of the workpiece. For large workpieces with less stringent clamping requirements, a vacuum generator can be an option.

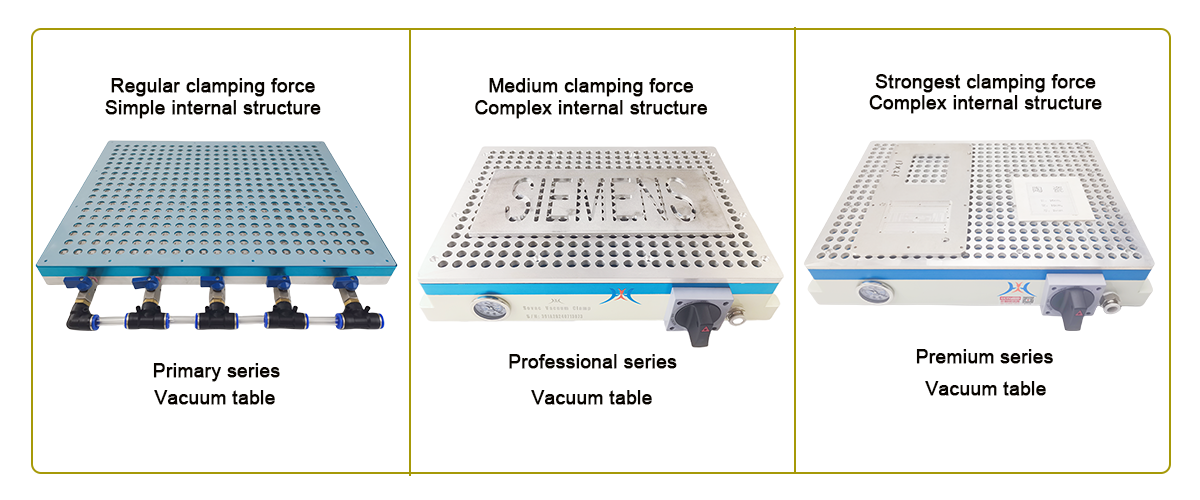

SOVAC vacuum tables come in three series: Primary, Professional, and Premium. Choosing the most appropriate series of vacuum tables is crucial for machining workpieces of varying materials. For dry machining, the Primary series is generally recommended. This series features a simpler interior and is well-suited for environments with high concentrations of dry powder.

Small amounts of powder debris will be sucked into the vacuum table through the horizontal gap between the workpiece and the clamping surface. These debris are sucked in from these suction hole below the workpiece. Since the minimum flow area of the SOVAC suction hole valve is a circular channel with a diameter of 2mm, powder debris with a diameter much smaller than 2mm will not cause the suction hole valve to become clogged and fail. However, during use, it is still required to connect the vacuum table to compressed air. After machining each workpiece, use a dust blower to blow away the powder debris scattered on the surface of the vacuum table, then turn off the vacuum table, and then connect compressed air to back blow the vacuum table. This ensures the cleanliness of the interior of the vacuum table and extends the service life of the vacuum table.

The above is the operating method for using the SOVAC vacuum table to dry machining workpieces. If you need to use the vacuum table to dry machining non-magnetic thin plates, please send an email for consultation.