For the CNC precision machining of some non-magnetic thin plate workpieces, we often use a vacuum table to fix them. Different countries have different names for this vacuum table. T-slot vacuum table, grid vacuum table, vacuum table with gasket, and a new type of multi-suction hole vacuum table. When using these vacuum tables. and using cutting fluid to cool the milling cutter, a small amount of cutting fluid will be sucked into the inside of the vacuum table along with the vacuum gas, and then it will be pumped into the gas tank of the vacuum pump. These cutting fluids will affect the normal work of the vacuum pump. So we need to find a way to separate these cutting fluids from the vacuum.

The traditional approach is to add a fluid storage tank between the vacuum table and the vacuum pump. When the level of the cutting fluid accumulated in the fluid storage tank reaches a certain height, we temporarily stop the operation. Open the drain valve at the bottom of the fluid storage tank to drain the cutting fluid, then close the drain valve and resume the processing. If we only use one CNC milling machine, these problems are easy to solve. But if we are using multiple milling machines at the same time, and the cutting fluid accumulates very quickly. By pausing the processing operation and manually draining the cutting fluid, it will affect our work efficiency and increase the workload of the workers.

Therefore, a fully automatic vacuum liquid separator would be a good choice. In the United States, it is usually called a vacuum liquid trap. In Europe, people usually call it a vacuum coolant separator. In China, people usually call it a vacuum automatic drainer. Of course, this is just a different name in different places. But the role of this device is the same. It is to achieve fully automatic separation of cutting fluid. Without suspending the processing operation, the cutting fluid is automatically separated from the vacuum hose or gas tank, and the vacuum pressure will not be reduced. The clamping force of the vacuum table is maintained.

| Product name | Vacuum Automatic Liquid Separator |

| Model | CS-SM-220 |

| Voltage | AC220V Single phase 50Hz 6W |

| Drainage interval time | Setup free, adaptive adjustment |

| Maximum liquid separation rate | 5.2L/min |

| Maximum gas flow rate | 700L/min |

| Dimension | 415mm×260mm×110mm |

How does the automatic vacuum cutting fluid separator work?

The automatic vacuum cutting fluid separator uses gravity to separate the liquid by taking advantage of the greater density of liquid and air. It mainly separates the liquid without reducing the vacuum pressure by dividing and switching multiple chambers. During use, due to the presence of debris in the cutting fluid, a filter cup needs to be installed at the front end of the automatic vacuum cutting fluid separator. Place the cutting debris into the automatic vacuum cutting fluid separator.

What are the features of automatic vacuum cutting fluid separator?

- The process of separating liquids does not reduce vacuum pressure.

- Small size, portable.

- Low power consumption, energy saving and electricity saving.

- Stainless steel inner wall, the inner cavity will not rust after long-term use.

- Affordable, will not increase the cost much.

- No need to do any settings before use, just connect the power supply and air pipe and you can use it.

- Fully automatic separation of liquids, the more liquid enters, the faster the liquid separation speed.

- Global supply, can be delivered to any city in the world

Installation location of automatic vacuum liquid separator

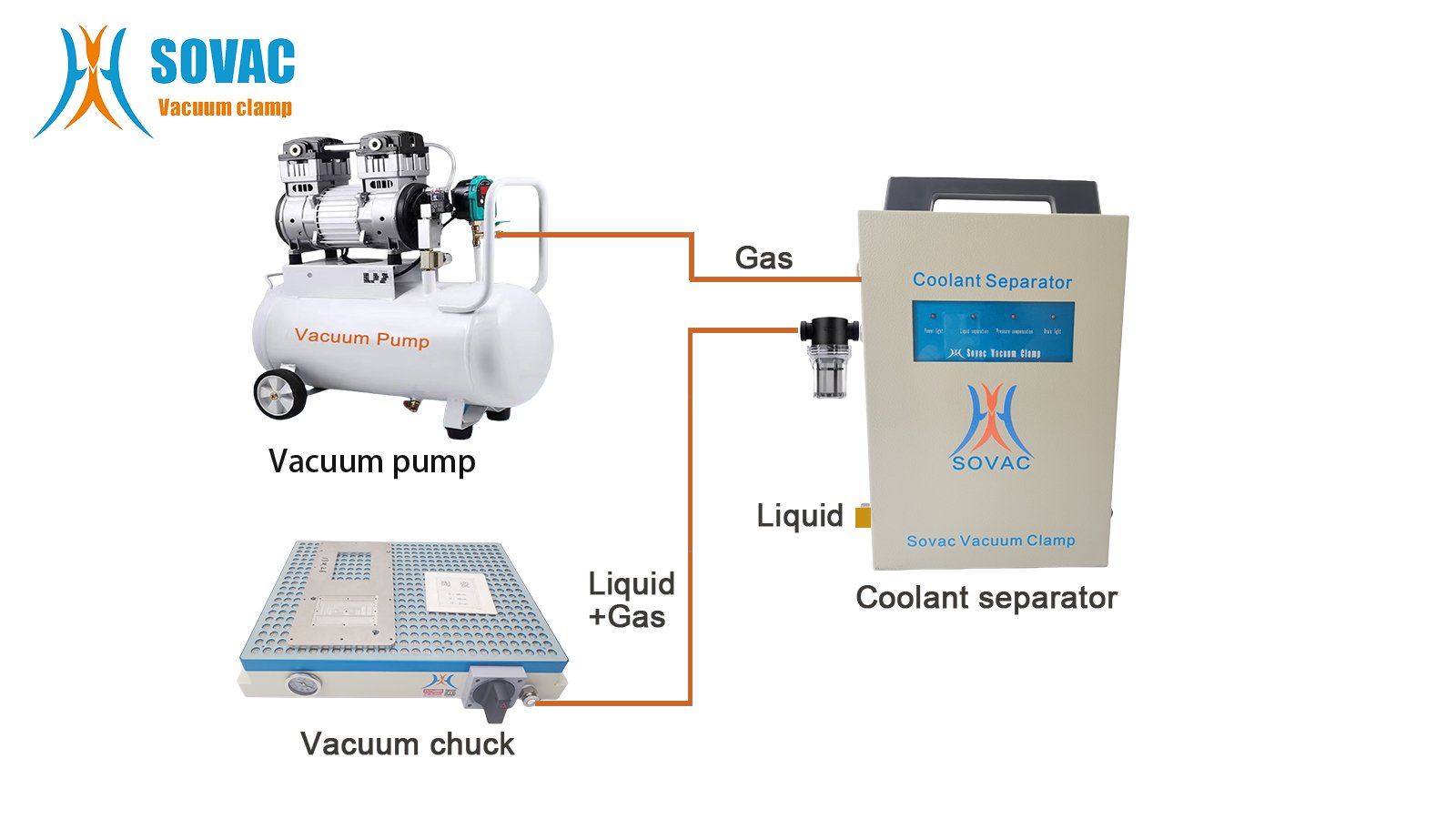

There are generally two options for the connection position of the automatic vacuum cutting fluid separator. One is to connect between the vacuum table and the vacuum pump, and the other is to connect to the bottom of the vacuum gas tank. This situation is more common when using multiple vacuum tables. Of course, if you are not using a vacuum pump, but a vacuum generator to convert the positive pressure of the air pressure into vacuum pressure, the same principle applies.

A schematic diagram shows the two connection methods.

For the second connection method, if the cutting fluid speed is relatively fast, we can add multiple automatic vacuum cutting fluid separators to increase the separation speed of the liquid. For details, please refer to the liquid separation speed of the automatic vacuum cutting fluid separator (5.2L/min).

For these two equipment connection methods, the vacuum table’s requirements for vacuum flow rate should also be considered when choosing. If it is the connection method 1. Since the automatic vacuum cutting fluid separator is connected between the vacuum table and the vacuum pump, it may reduce the vacuum flow rate in the vacuum hose. The maximum flow rate of the automatic vacuum cutting fluid separator is 700L/min. If the user has requirements for the flow rate of the vacuum tube. For example, if the vacuum flow rate required by the main manifold reaches 1600L/min, the automatic vacuum cutting fluid separator will reduce the clamping force of the vacuum table. For the requirements of larger vacuum flow, it can be customized separately or connected according to the second connection method. In the second equipment connection method, the automatic vacuum cutting fluid separator is connected to the branch flow, so it will not limit the vacuum flow rate of the main manifold. If you do not have detailed parameter data for your own equipment parameters and requirements, you can consult our professional engineers. Ensure that your cutting fluid can enter the vacuum problem well, and will not affect the clamping force of the vacuum table.

What precautions should be taken during use?

- Since it is a gravity-type cutting fluid separator, the automatic vacuum cutting fluid separator must stand vertically during use. Tilt-type use is not allowed.

- For the needs of larger vacuum flow rates, it is necessary to make a good selection.

- Choose a suitable installation location to ensure better liquid separation requirements.

- If there are debris mixed in the liquid, a filter cup must be installed in the automatic vacuum cutting fluid separator. If the cutting debris enters the automatic vacuum cutting fluid separator for a long time, it will cause the seal between the chambers of the automatic vacuum cutting fluid separator to fail prematurely.

The above content is only a solution for the CNC machining industry. This automatic vacuum cutting fluid separator can also be used in the semiconductor manufacturing industry, medical industry and other scenarios where liquid needs to be prevented from entering the vacuum pump.