The auto-valve multi-hole vacuum table is a new type of vacuum table. It is different from the traditional grid vacuum table and groove vacuum table, and it is also different from the multi-hole vacuum table that covers the air suction holes on the periphery of the workpiece with soft rubber pads. An automatic valve is designed inside each air suction hole to automatically close or open according to the air pressure difference.

When the workpiece is placed on the surface of the auto-valve multi-hole vacuum table and the vacuum switch is turned on, the vacuum will instantly enter the auto-valve multi-hole vacuum table. Because the air suction holes on the periphery of the workpiece are exposed to the air, the pressure difference formed instantly causes the internal valve to close. The suction holes covered by the workpiece cannot be closed because the atmospheric pressure is blocked by the workpiece, and the vacuum will pass through the valve and rise to the lower surface of the workpiece. In this way, a pressure difference is formed on the upper and lower sides of the workpiece. And the more suction holes covered by the workpiece, the greater the pressure generated. This is the working principle of the auto-valve multi-hole vacuum table.

What are the advantages of the auto-valve multi-hole vacuum table? Mainly in the following aspects.

- There is no need to install sealing ropes, and there is no need to cover the suction holes that are not covered by the workpiece, which improves the clamping speed.

- For ultra-thin (0.3-5mm) workpieces, such as glass, silicon carbide, ceramics, and PCB boards with holes in the semiconductor industry, it can ensure that the workpiece maintains good flatness during the entire clamping process to avoid warping.

- It can clamp thin plates with holes, and the workpiece can be milled through during processing without reserving a certain thickness of the bottom.

- The automatic valve multi-hole vacuum table can be upgraded to a semi-automatic vacuum workbench controlled by PLC.

- It can be used on a rotary surface grinder or thinning machine. There is no need to worry about the suction hole being blocked and failing.

- It can be used on a large-size workbench in a four-axis machining center. (The vacuum hose interface will be designed in the center of the bottom of the auto-valve multi-hole vacuum table)

- Due to the combined design of the auto-valve multi-hole vacuum table body and the replaceable aluminum alloy plate, the aluminum alloy replacement plate can mill the surface to ensure the flatness of the adsorption table and the verticality of the spindle, and the processing accuracy of the workpiece is relatively high. The drill is allowed to mill through the workpiece without reserving a certain thickness of the bottom.

- For some workpieces that use grid vacuum tables and are inconvenient to install sealing strips to clamp the workpieces, the auto-valve multi-hole vacuum table can do the job well.

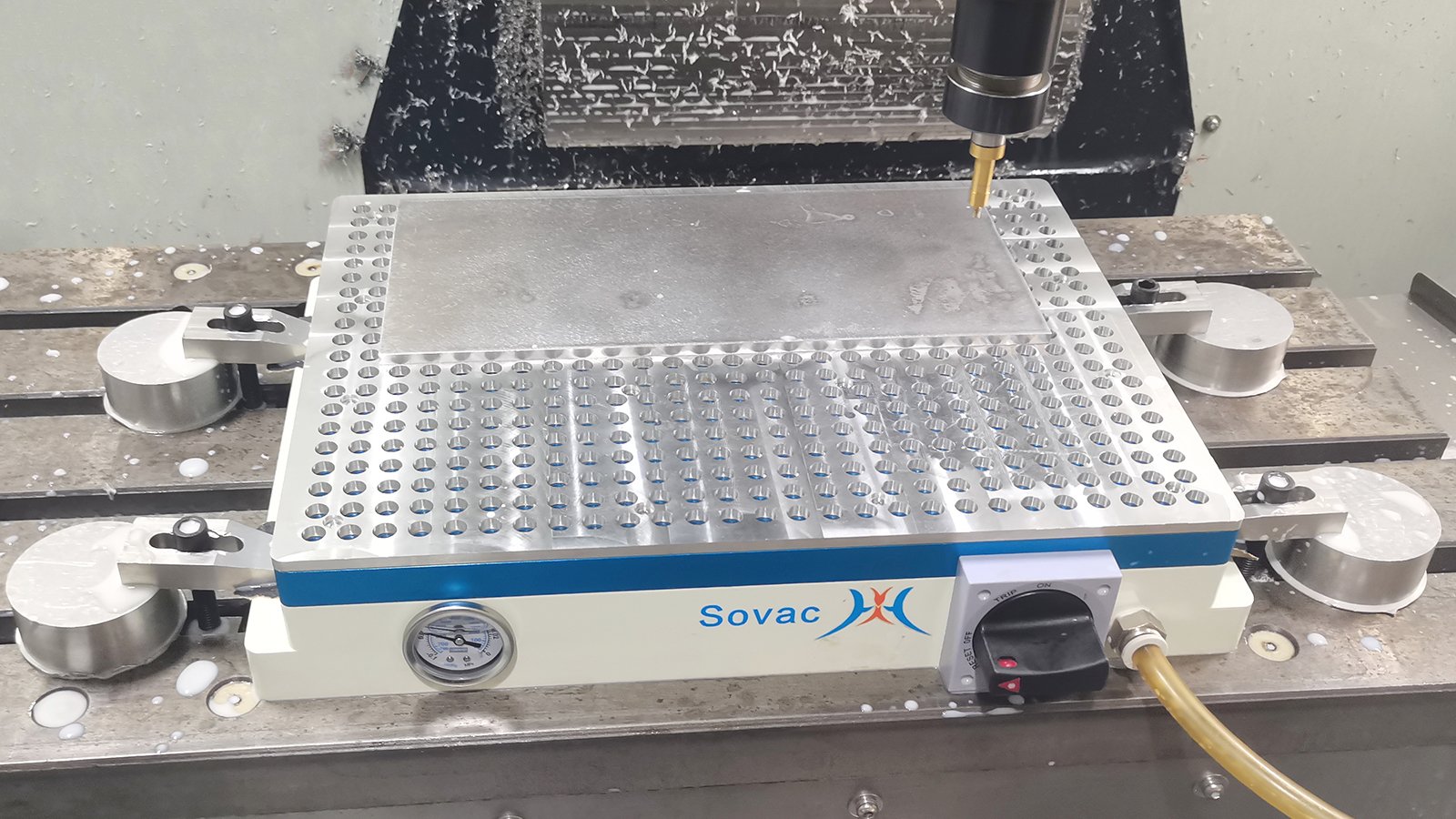

- You can boldly turn on the coolant to cool the cutting tool.

What are the disadvantages of the auto-valve multi-hole vacuum table?

- Since the effective pressure difference area is smaller than that of the grid vacuum table, the suction force is not as strong as the clamping force of the traditional grid vacuum table, and the feed parameters of the tool need to be controlled.

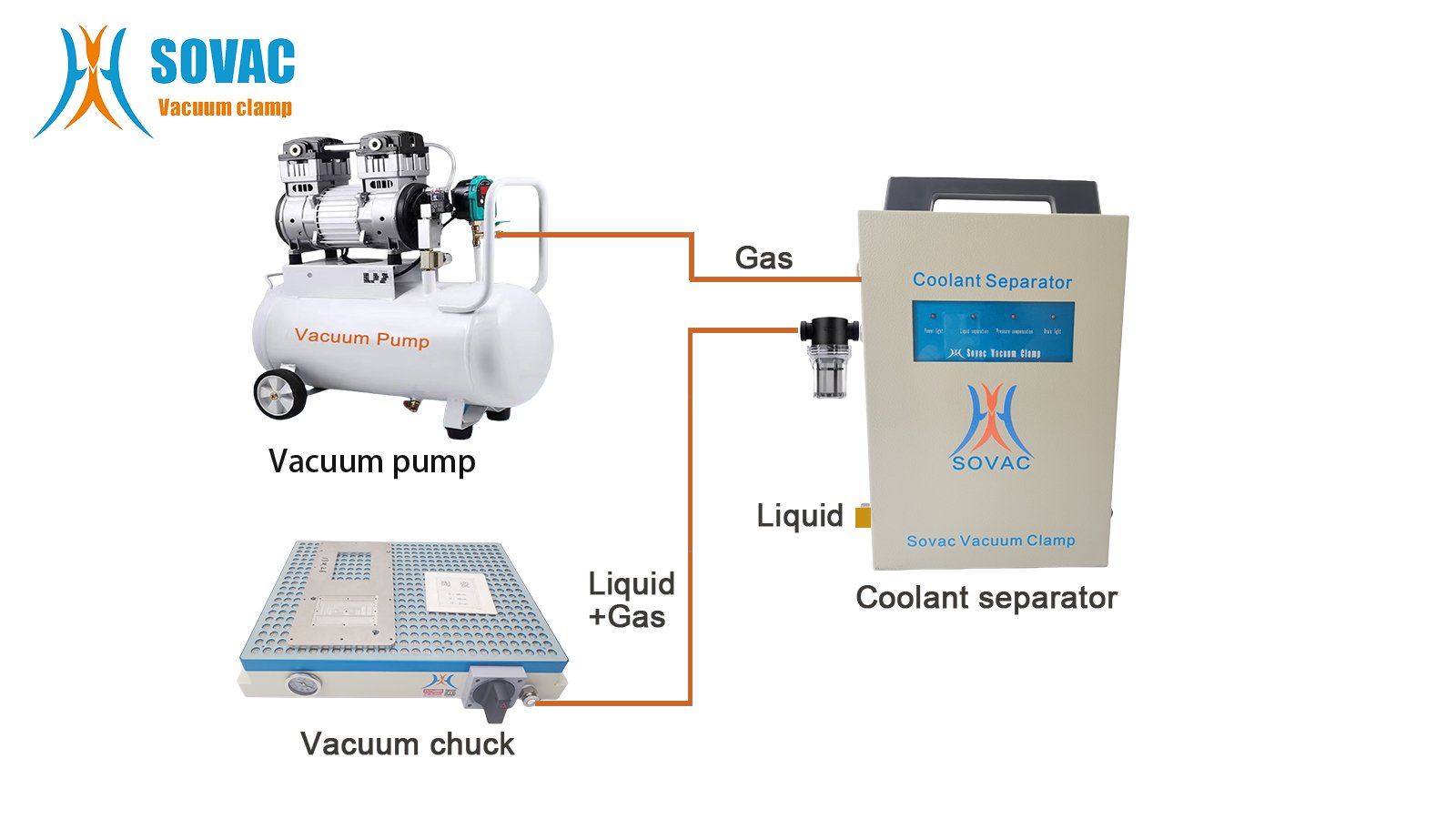

- Since there is no sealing rope, the speed at which the cutting fluid is sucked into the auto-valve multi-hole vacuum table will be much faster than that of the grid vacuum table, and a coolant separation device needs to be installed. In this regard, our company has specially developed a portable vacuum pump automatic liquid separator.

- Since it is necessary to provide sufficient instantaneous pressure difference for all valves inside the suction hole at the moment of turning on the switch, and a small amount of air will enter from the gap between the workpiece and the auto-valve multi-hole vacuum table surface, a large-displacement vacuum pump needs to be configured. Of course, the ultimate vacuum degree of the vacuum pump is close to -100KP (760mmHg) is the best. Traditional grid vacuum tables do not need to consider starting hundreds of valves, so high vacuum and low flow rate vacuum are generally used. In most cases, a vacuum generator can do the job. However, using an automatic valve porous vacuum suction cup may require users to purchase a new vacuum pump.

- Due to the more complex internal structure, the cost is definitely more expensive than the grid vacuum table.

- If the internal valve design is unreasonable, there is a risk of blockage and failure of the suction hole during long-term use.

What is special about auto-valve multi-hole vacuum table from SOVAC?

- The internal valve adopts a spring-free structure, which is a smart design. In 2019, we designed a spring-structured valve, but we found that the spring-structured valve has fatal defects. It has the problem of spring fatigue failure after a period of use, and the filter screen of the suction hole cannot be blocked. However, the non-spring structure valve we developed can solve this problem well. Therefore, the auto-valve multi-hole vacuum table produced by our company can be used on a surface grinder to grind some ceramics, graphite, fiberglass and other materials. So that these materials will produce a lot of powdery debris during milling or grinding. But it can still avoid clogging.

- The world’s only vacuum table body base and replacement plate combination design is adopted. This design can well protect the body of the auto-valve multi-hole vacuum table from being damaged by the cutting tool. At the same time, it allows the workpiece to be completely milled through. The overcutting cutting tool will leave a very shallow groove on the surface of the replacement plate. After using it for a period of time, we only need to mill the surface of the replacement plate again. When the thickness of the replacement plate is insufficient after a period of use, the user can process a new replacement plate according to the electronic drawing of the replacement plate provided by us. No spare parts need to be purchased from the manufacturer. The material of this replacement plate can be replaced with other materials besides aluminum alloy as needed.

- Automatic cleaning design is adopted. After the auto-valve multi-hole vacuum table is used for one day, we only need to rotate the switch to the half-open position. At this time, the auto-valve multi-hole vacuum table will automatically exhaust. Sprinkle some clean water on the surface of the auto-valve multi-hole vacuum table, and the clean water will be quickly drawn into the interior of the auto-valve multi-hole vacuum table, and the internal valve and the inner cavity of the auto-valve multi-hole vacuum table will be cleaned. This top-down cleaning method can achieve a good cleaning effect.

- Splicing structure design is adopted. When the user buys a smaller auto-valve multi-hole vacuum table, he suddenly encounters some large-sized parts that need to be processed. We do not need to clamp a larger-sized auto-valve multi-hole vacuum table, but purchase an auto-valve multi-hole vacuum table interface of the same size and model. Two auto-valve multi-hole vacuum tables can be spliced. It can be spliced along the wide side or along the long side. This allows us to get a auto-valve multi-hole vacuum table with a wider clamping range at a lower cost.

- We have equipped the auto-valve multi-hole vacuum table with a vacuum automatic coolant separator. This will prevent the cutting fluid sucked into the auto-valve multi-hole vacuum table from entering the vacuum. It protects the vacuum pump well. The separated cutting fluid can be automatically separated and sent back to the sink of the machining center. This is much more convenient than using a large manual volume tank.

- Small suction holes can be designed by designing the size of the perforated holes of the replacement plate. This is very necessary when clamping some brittle or flexible thin plate materials.

- The suction force of a single suction hole can be customized according to the needs of the user. For example, a gold foil or a flexible thin sheet can be designed with a small suction force. Ensure that the thin sheet is not deformed or dented by suction.

How should we choose a vacuum pump for the auto-valve multi-hole vacuum table?

As mentioned above, traditional vacuum generators or small-displacement vacuum pumps may not be competent, so it is best to consult us or our dealers about the selection of vacuum pumps before purchasing. I especially recommend oil-lubricated rotary vane vacuum pumps. Its high flow rate and high vacuum performance can well meet the use requirements of our auto-valve multi-hole vacuum table. Generally, the limit vacuum pump of the vacuum pump is required to be above -95KPa. The flow rate of vacuum is greater than 220L/min (13.2m³/h). If we use a vacuum generator, we need to choose a vacuum generator with a large flow rate. According to the Venturi tube principle, this will consume a lot of compressed gas, and this solution is very energy-consuming. It can be used for short-term emergency use, but it is not recommended for long-term use.

Which workpieces do the auto-valve multi-hole vacuum table can better play its advantages when processing?

- Ultra-thin workpieces (thickness 0.3mm~10mm), the entire adsorption working surface has a good flatness, and high-precision processing can be obtained for some ultra-thin workpieces. When installing the replacement plate, the workpiece processing progress can reach 0.01mm)

- The workpiece already has some through holes before processing, which is not suitable for grid vacuum table clamping.

- Rotary surface grinder for ultra-thin workpiece clamping and grinding.

- For some flexible materials, such as flexible printed circuit boards. It does not require strong suction, but requires good flatness of the adsorption surface.

If you have any questions about this auto-valve multi-hole vacuum table, please feel free to contact our engineers.

Release by Ditrong Dai (Email:ditrong@outlook.com)