Automatic liquid trap for vacuum pump can bring more convenience when more liquids need to be separated in a large flow system. A common scenario is when using a vacuum table, a large amount of cutting fluid will be pumped into the vacuum pipeline. If these cutting fluids are not separated, it will damage the vacuum pump. So we must separate the liquid through the air-liquid and liquid separation device. The conventional practice is to use a liquid collection tank. When a certain volume is collected, the liquid is drained through the drain valve at the bottom of the liquid collection tank. However, this requires the vacuum system to be temporarily stopped to complete the operation. If we don’t want the vacuum system to stop and can also separate the liquid, we need an automatic liquid trap for vacuum pump.

Automatic liquid trap for vacuum pump can ensure that cutting fluid or other liquids are automatically separated from the vacuum pipeline without stopping the vacuum system. It can greatly improve the work efficiency.

And because the automatic liquid trap for vacuum pump has a high efficiency in separating liquids and will not reduce the vacuum pressure in the vacuum pipeline, the automatic liquid trap for vacuum pump will be used in many industrial production.

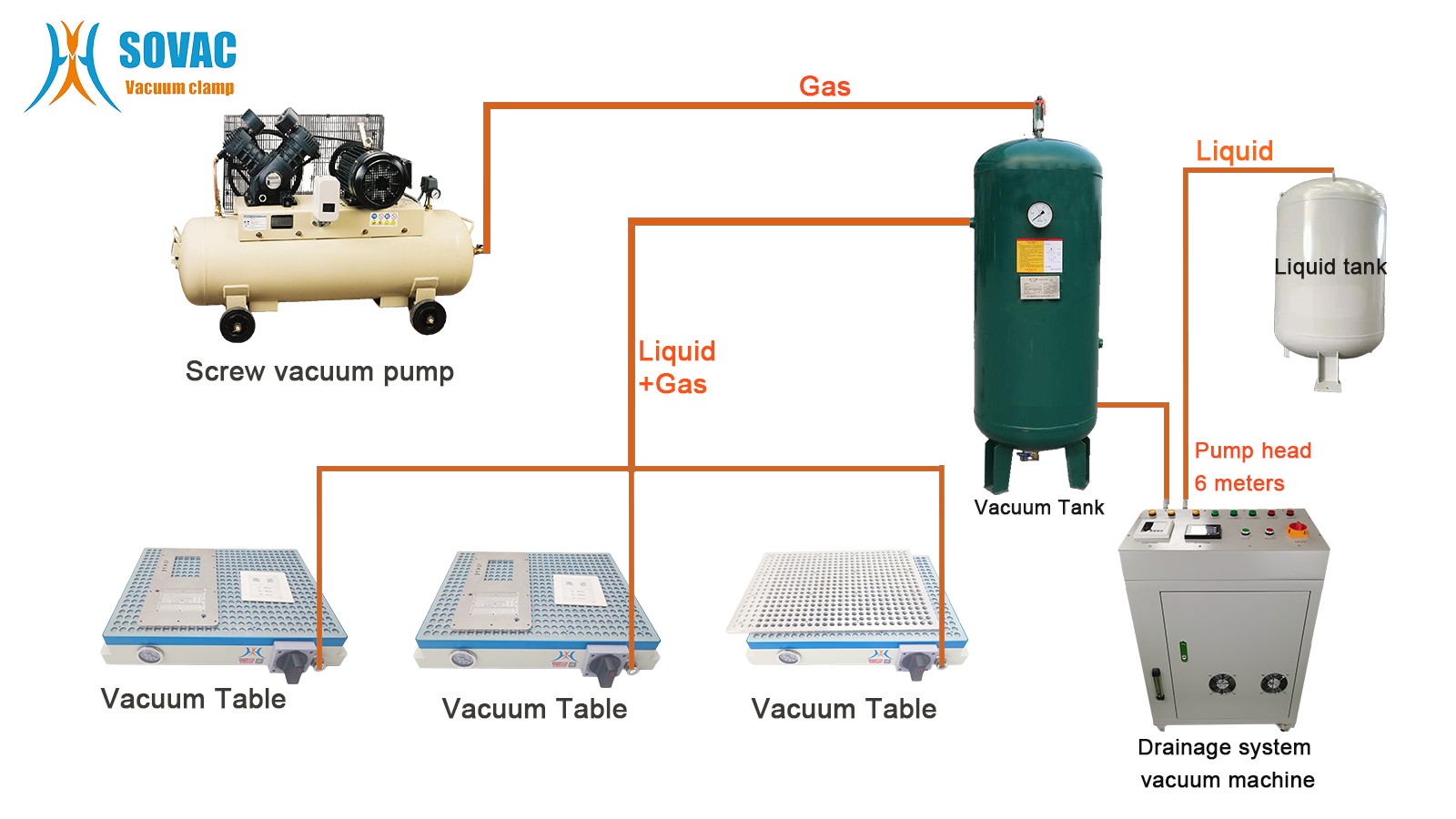

How is the automatic liquid trap for vacuum pump connected? The automatic liquid trap for vacuum pump is usually connected to the front section of the vacuum pump to separate the liquid in the vacuum pipeline in advance. It can also be connected to the bottom of a large liquid storage tank, where the liquid is first collected through the liquid storage tank, and then the liquid is pumped into the automatic liquid trap for vacuum pump and finally discharged. In the CNC processing industry, a vacuum table is sometimes used to clamp the workpiece. If there is only one CNC milling machine, we can connect the automatic liquid trap for vacuum pump to the front end of the vacuum pump. If multiple CNC milling machines are in use, the cutting fluid is generally collected in a large liquid storage tank. At this time, we can connect the automatic liquid trap for vacuum pump to the map of the liquid storage tank. Below are two equipment connection diagrams for reference.

Here are some technical parameters of the automatic liquid trap for vacuum pump for reference. But I need to remind potential users to pay attention to the vacuum flow rate in your vacuum pipeline and the liquid speed to be separated, and make sure that these two parameters of the automatic liquid trap for vacuum pump are greater than your vacuum flow rate and liquid separation speed. In this way, the use of automatic liquid trap for vacuum pump will not reduce the flow rate in the vacuum pipeline, and at the same time all the liquid can be separated cleanly.

| Product name | Automatic Liquid Trap for vacuum pump |

| Model | CS-SM-220 |

| Voltage | AC220V Single phase 50Hz 6W |

| Protection grade | IPX7 |

| Drainage interval time | Setup free, adaptive adjustment |

| Maximum liquid separation rate | 5.2L/min(1.4GPM) |

| Maximum gas flow rate | 700L/min(25CFM) |

| Working temperature | 0~300℃(572°F) |

| Operating pressure range | 0~-100KPa(-750mmHg) |

| Material | SUS304 stainless steel inner cavity, plastic-sprayed galvanized steel shell |

| Product weight | 22kg(48.5lb) |

| Packing weight | 25kg(55lb) |

| Dimension | 415mm×260mm×110mm |