Vacuum table usage tutorial, How to use multi-hole vacuum table, Characteristics of multi-hole vacuum tables,how to maintain multi-hole vacuum tables, What are the advantages of multi-hole vacuum tables,How to select a vacuum table,How to Use a Vacuum Table,How to prevent cutting fluid from entering the vacuum pump,Comparison with Grid Vacuum Table,How multi-hole vacuum tables work

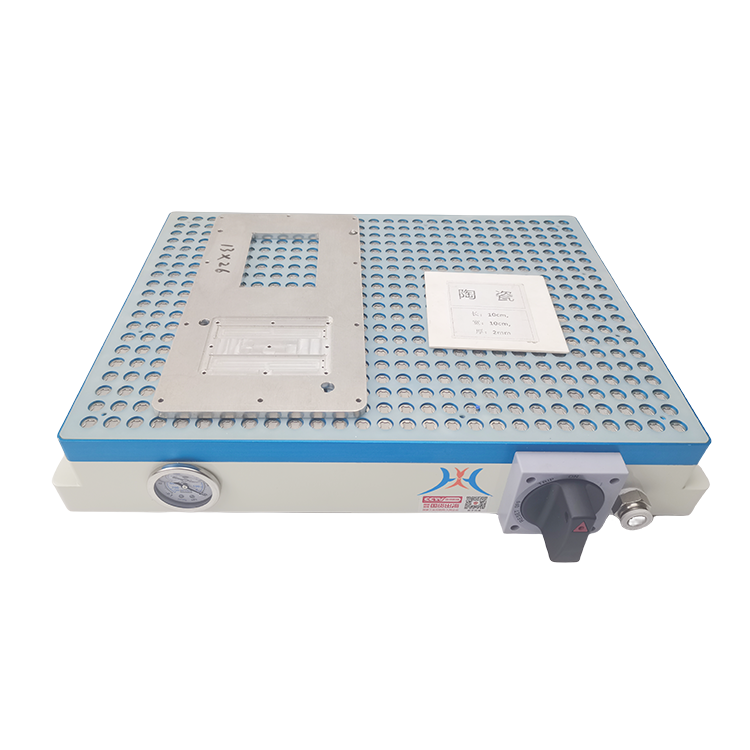

The multi-hole vacuum table is also called a cordless vacuum table. The multi-hole vacuum table is mainly used for fast clamping and fixing of non-magnetic thin plate workpieces to achieve CNC precision machining of the workpieces.

Compared with the traditional grid vacuum table or T-slot vacuum table, it has hundreds or thousands of more suction holes, and no rubber sealing rope is required. An air pressure difference sensing valve is installed inside each suction hole. When the air pressure difference exceeds a certain value, the valve will automatically close. However, the overall suction force will be smaller than that of the grid vacuum table. In the process of clamping the workpiece, if the cutting fluid is used to cool the cutting tools, a small amount of cutting fluid will enter the vacuum table.

Because the multi-hole vacuum table is a brand-new product, it is necessary to make a detailed introduction to the use of the multi-hole vacuum table.

- Installation method

The installation method is the same as that of the traditional grid vacuum table. The vacuum table needs to be fixed on the workbench with a pressure plate.

- Equipment connection

Since the multi-hole vacuum table consumes more gas than the grid vacuum table, it is generally not recommended to use a vacuum generator, but a large-displacement vacuum pump is recommended. At the same time, the amount of cutting fluid entering the multi-hole vacuum table will be more, so a liquid separator must be installed between the vacuum table and the vacuum pump. It can be a liquid storage tank or an automatic liquid separator for a vacuum pump. Through this connection method, the cutting fluid entering the multi-hole vacuum table is separated to prevent the cutting fluid from entering the vacuum pump.

- Install a replaceable aluminum plate

This replaceable aluminum plate is a design that fully considers the customer. Because most processing will mill through the workpiece, this replaceable aluminum plate ensures that the milling cutter will not mill the body of the multi-hole vacuum table. When we mill through the workpiece, the overcut part will go deep into the replaceable plate. After using it for a period of time, we only need to use an end-flat milling cutter to smooth the surface of the replaceable plate. Regain a smooth and flat working surface.

- Milling surface treatment of the surface of the replaceable plate

When the surface of the replaceable aluminum plate we get from the manufacturer is generally not smooth enough, we must wash the surface first when using it for the first time. Ensure that the upper surface of the replaceable plate has good parallelism and flatness. This is also one of the requirements for improving the processing accuracy of the workpiece.

- Place the workpiece on the surface of the replaceable plate.

Since there is no rubber sealing rope, the adsorption surface of the workpiece is required to have good finish and parallelism. At the same time, in order to cover a certain number of suction holes, the size of the workpiece is required to be no less than 10cm*10cm. Ensure a certain suction force.

- Turn on the negative pressure switch of the multi-hole vacuum table.

In this process, the workpiece must be placed first, and then the switch is turned on. Let the multi-hole vacuum table automatically identify whether the suction hole is covered by the workpiece. If the switch is turned on first and the workpiece is placed later. All the suction holes will be closed instantly, and no suction will be generated.

- Get the position data of the four sides of the workpiece

Measure and get the position data of the four sides of the workpiece through the edge finder or the centering rod.

- Execute the processing program

During the execution of the processing program, as the cutting fluid is sprayed on the multi-suction hole vacuum table, a small amount of cutting fluid will enter the inside of the vacuum table. Since the liquid separation device is installed, there is no need to worry about the cutting fluid entering the vacuum pump.

- Remove the workpiece

After executing the processing program, we need to use an air gun to blow away the debris on the surface of the multi-hole vacuum table. Then turn off the switch of the multi-hole vacuum table, and the vacuum suction cup will lose suction immediately. We can easily remove the workpiece from the multi-hole vacuum table.

- Clean regularly every day

When you get off work every day, be sure to clean the inside of the vacuum table. Turn the switch of the vacuum table from the stop position to the start position 30 degrees, and you will hear the vacuum table pumping air. At this time, pour a little clean water on the surface of the vacuum table, and the clean water will be quickly pumped into the inside of the vacuum table and separated by the liquid separator. Keep cleaning for 30 seconds until the clean water is completely drained.

11. Install the positioning pin

If we process the same workpiece in batches, we can drill 4 small holes in the appropriate positions of the replaceable plate, respectively, in the X and Y axis directions. In this way, the second workpiece can be accurately positioned.

12. Small workpieces are processed by typesetting

If the size of the small workpiece we want to process is less than 10cm*10cm, we can use typesetting. When compiling the cutting program, reserve a 0.1mm bottom between the workpieces. After executing the processing program, we can manually separate the small workpieces with a deburring knife. Then do a deburring treatment on the edge.

The above are some general procedures I have summarized for using the SOVAC multi-hole vacuum table. If you also have the need to use this multi-hole vacuum table, you can click the link below. Contact the manufacturer for consultation and purchase.